The Pivotal Role of Strong Base Anion Exchange Resins in Industrial Purity

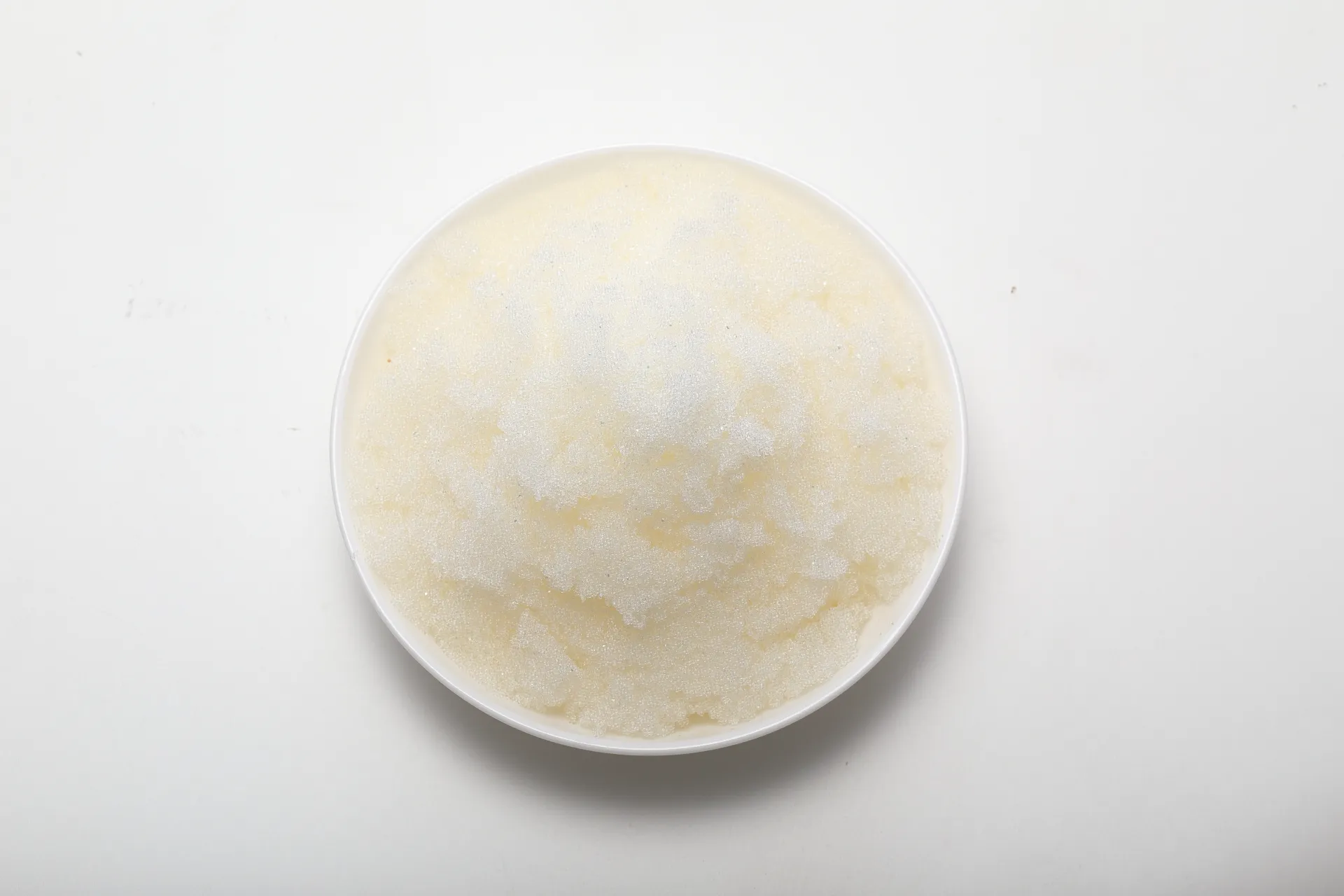

In the intricate landscape of industrial water treatment and chemical processing, efficient ion exchange technologies are paramount for achieving desired purity levels and operational efficiency. Among these, strong base anion exchange resins stand out as indispensable tools. These highly effective polymeric materials are engineered to remove anions from liquid streams, playing a critical role in demineralization, contaminant removal, and product purification across a vast array of sectors. Their robust chemical structure and high affinity for anions make them central to processes demanding exceptional water quality and process fluid integrity.

Manufacturing Process Flow of Strong Base Anion Resins

The production of a high-performance strong base anion resin involves a sophisticated multi-stage chemical engineering process, meticulously controlled to ensure consistency, purity, and optimal functional characteristics. These resins, often based on a styrene-divinylbenzene copolymer matrix, are designed for maximum stability and ion exchange capacity.

- Monomer Preparation & Polymerization: The process begins with the careful preparation of styrene and divinylbenzene (DVB) monomers. DVB acts as a cross-linking agent, providing the structural integrity and insolubility of the final resin bead. Suspension polymerization is commonly employed, where an aqueous phase containing a stabilizer is used to suspend droplets of the monomer mixture. Heating initiates the polymerization, forming spherical copolymer beads (matrix) of a controlled size distribution. This stage is crucial for defining the resin’s physical strength and porous structure.

- Functionalization (Chloromethylation & Amination): The inert polymer matrix must then be functionalized to introduce the active ion exchange sites. The beads undergo chloromethylation, where chloromethyl groups are attached to the aromatic rings of the styrene units. Subsequently, these chloromethyl groups react with tertiary amines (e.g., trimethylamine for Type I resins or dimethylethanolamine for Type II resins) in an amination step. This reaction introduces quaternary ammonium functional groups, which are responsible for the strong basicity and anion exchange capability of the resin. Type I strong base resin typically uses trimethylamine, resulting in higher alkalinity and thermal stability, while Type II offers slightly easier regeneration.

- Washing, Sizing, and Quality Control: After functionalization, the resin beads are thoroughly washed to remove unreacted reagents and byproducts. They are then subjected to sizing, where beads are separated by size to meet specific application requirements. Rigorous quality control measures are implemented throughout the entire manufacturing process.

- Testing and Packaging: Final products undergo comprehensive testing for key parameters such as total exchange capacity, moisture content, specific gravity, effective size, uniformity coefficient, and osmotic stability, adhering to international standards like ASTM and ISO. These tests ensure the resin meets stringent performance and safety specifications before being packaged for distribution.

Target industries benefiting from these highly engineered materials include petrochemical, metallurgy, power generation, semiconductor manufacturing, and municipal water supply & drainage. The manufacturing process emphasizes precision to deliver resins that offer distinct advantages such as extended service life, energy saving due to efficient regeneration, and superior corrosion resistance in system components by effectively removing corrosive anions.

Industry Trends and Market Dynamics

The market for strong base anion resin is dynamic, driven by increasing global demand for clean water, stricter environmental regulations, and the expansion of industries requiring high-purity process fluids. Key trends include:

- Growing Demand for Ultrapure Water: Industries such as semiconductor manufacturing, pharmaceuticals, and power generation continuously demand higher purity water, driving innovation in resin technology, including macroporous and monodisperse resins for enhanced kinetics and efficiency.

- Environmental Compliance: Stricter discharge limits for pollutants like nitrates, perchlorates, and sulfates are increasing the adoption of strong base anion exchange resins for selective removal from wastewater streams.

- Focus on Sustainability: Manufacturers are developing more regenerant-efficient strong base resins and processes to reduce chemical consumption and waste generation, aligning with global sustainability goals.

- Resilience and Longevity: There’s a persistent trend towards resins with improved physical stability, osmotic shock resistance, and thermal resistance to extend service life and reduce operational costs, particularly important for challenging industrial environments.

The global ion exchange resin market, valued at approximately $1.5 billion in 2022, is projected to grow at a CAGR of over 4% from 2023 to 2030, with strong base anion exchange resin playing a significant role due to its versatility and critical applications across diverse sectors.

Technical Specifications: Strong Base Anion Exchange Resin 201X4 FG

The Strong Base Anion Exchange Resin 201X4 FG exemplifies advanced resin technology, tailored for high-efficiency demineralization and specific anion removal. Its design prioritizes robust performance and reliability in demanding industrial applications.

Product Data Sheet: 201X4 FG

Comparison: Type I vs. Type II Strong Base Anion Resins

Understanding the distinction between Type I and Type II strong base anion resin is crucial for optimal application selection.

Key Application Scenarios and Versatility

The robust functionality of strong base anion exchange resins makes them indispensable across a multitude of industrial processes. Their ability to effectively remove both strong and weak acids, including silica and carbon dioxide, is a cornerstone of many critical operations.

- Demineralization and Ultrapure Water Production: In combination with strong acid cation resins, these resins form the core of demineralization systems, producing high-purity water for boiler feed, electronics manufacturing, pharmaceuticals, and laboratory use. They ensure complete removal of anions like chloride, sulfate, nitrate, bicarbonate, and crucial silica.

- Acid Removal: Efficiently remove acids from process streams, protecting downstream equipment from corrosion and maintaining product quality in chemical manufacturing.

- Organic Matter Removal: Certain macroporous strong base anion resin varieties are particularly effective at adsorbing and removing problematic organic compounds that can foul other treatment media or compromise product quality.

- Sugar Decolorization and Demineralization: In the food and beverage industry, they are used to remove color bodies and inorganic salts from sugar solutions, improving product appearance and purity.

- Uranium Recovery: In mining and hydrometallurgy, specific strong base resin formulations are engineered to selectively extract uranium from leach liquors.

- Nitrate Removal: Critical for potable water treatment to reduce nitrate concentrations to safe levels, particularly in agricultural regions.

Customer feedback consistently highlights the reliability and consistent performance of high-quality strong base anion exchange resins, even under fluctuating feed water conditions, which translates to fewer unscheduled downtimes and reduced operational complexities.

Technical Advantages and Performance Excellence

The selection of a premium strong base anion resin offers significant technical advantages that contribute to optimized plant operation and lower total cost of ownership:

- High Exchange Capacity: Designed with a high density of functional groups, these resins possess an excellent capacity to exchange anions, leading to longer service cycles between regenerations and reduced chemical consumption.

- Exceptional Thermal Stability: Type I strong base anion resins, in particular, exhibit superior thermal stability, allowing them to operate effectively in applications with elevated temperatures (up to 80°C), without significant degradation or loss of capacity. This is critical in power generation and high-temperature process streams.

- Osmotic and Physical Durability: The robust copolymer matrix provides excellent resistance to osmotic and mechanical shock. This durability translates to minimal bead breakage, reduced pressure drop, and an extended service life for the resin bed, minimizing replacement frequency.

- Efficient Regeneration: While requiring strong caustic (NaOH) for regeneration, modern strong base anion exchange resins are engineered for efficient regenerant utilization, reducing waste volume and operating costs. The complete removal of adsorbed anions ensures consistent effluent quality.

- Broad pH Operating Range: These resins maintain their stability and functional integrity across the entire pH spectrum (0-14), offering flexibility for various industrial applications without compromise.

- Superior Effluent Quality: Capable of achieving extremely low conductivity and silica levels in effluent, meeting the stringent requirements for ultrapure water systems.

These advantages underscore why high-quality strong base resin is a preferred choice for industries where performance, longevity, and operational efficiency are non-negotiable.

Vendor Comparison: Factors in Selecting a Strong Base Anion Resin Supplier

Choosing the right supplier for strong base anion resin is a strategic decision that impacts operational performance, cost-efficiency, and long-term reliability. Key factors to consider during vendor evaluation include:

A thorough vendor comparison ensures a partnership that supports both immediate project needs and long-term operational goals, maximizing the return on investment for your strong base anion resin solutions.

Customized Solutions for Specific Challenges

Recognizing that standard products may not always meet the unique demands of every industrial application, leading manufacturers offer customized strong base anion resin solutions. This bespoke approach allows for tailoring resin properties to optimize performance for specific feed water chemistries, operational parameters, and effluent quality targets.

- Optimized Bead Size Distribution: Customizing particle size can significantly impact pressure drop, kinetics, and filtration characteristics, crucial for maximizing efficiency in specific reactor designs.

- Tailored Porosity and Surface Area: Macroporous structures can be engineered for enhanced adsorption of large organic molecules, while gel resins are optimized for high capacity and demineralization.

- Specific Functional Groups: While primarily quaternary ammonium, fine-tuning the functional group density or even introducing hybrid functionalities can enhance selectivity for specific ions or improve resistance to fouling.

- Improved Chemical and Physical Stability: For extremely harsh environments, resins can be formulated with enhanced cross-linking or specialized polymer matrices to withstand aggressive chemicals or high temperatures.

Engaging with a manufacturer capable of developing these customized solutions ensures that the ion exchange system is perfectly integrated with your process, leading to superior performance, extended resin life, and often, significant cost savings over the long term. This expertise in material science and application engineering is a hallmark of truly authoritative suppliers in the strong base anion resin market.

Application Case Studies: Strong Base Anion in Action

Real-world applications demonstrate the critical value and performance capabilities of strong base anion resins:

Case Study 1: Ultrapure Water for Semiconductor Manufacturing

A leading semiconductor fabrication plant required ultrapure water with conductivity below 0.05 µS/cm and total organic carbon (TOC) levels below 5 ppb for chip rinsing. The existing ion exchange system struggled with inconsistent silica and TOC removal, leading to product rejection rates.

- Solution: Implementation of a high-capacity, macroporous strong base anion resin (e.g., a specialized 201X4 equivalent) in the polishing loop, downstream of a mixed bed.

- Results: The new resin demonstrated superior kinetics for trace anion removal, including silica. Effluent conductivity consistently met the target, and TOC levels were reduced by an additional 20%, contributing to a 15% reduction in product rejection rates and significant operational savings due to extended resin bed life and reduced regeneration frequency.

Case Study 2: Boiler Feedwater Demineralization in a Power Plant

A thermal power plant needed to upgrade its demineralization system to handle increased feedwater hardness and fluctuating raw water quality, targeting highly purified water to prevent boiler scaling and corrosion. High silica leakage was a persistent issue with their previous resin.

- Solution: A robust Type I strong base anion resin (such as the 201X4 FG product) was selected for the anion exchange column, preceded by a strong acid cation unit.

- Results: The new resin effectively handled the high anion load, achieving consistent silica removal to less than 20 ppb. The plant reported a 10% reduction in regeneration chemical consumption and an extended service run of 20% compared to their previous resin, leading to improved boiler efficiency and reduced maintenance costs.

These case studies underscore the measurable impact of selecting high-quality strong base anion exchange resin on industrial operations, demonstrating tangible improvements in water quality, operational efficiency, and cost savings.

Ensuring Quality: Certifications, Standards, and Authoritativeness

The reliability and safety of strong base anion exchange resin products are underpinned by stringent adherence to international quality standards and certifications. Reputable manufacturers ensure their products meet or exceed these benchmarks, providing customers with confidence in their investment.

- ISO 9001:2015 Certification: This widely recognized standard for quality management systems ensures that a manufacturer consistently provides products and services that meet customer and regulatory requirements. It signifies a commitment to continuous improvement and operational excellence throughout the production of strong base anion resin.

- NSF/ANSI 61 Certification: For resins used in potable water applications, NSF/ANSI 61 certification is paramount. It confirms that the product does not impart contaminants into drinking water at levels that could pose a health risk. This is a critical factor for municipal water suppliers and industries requiring treated water for human consumption.

- FDA Compliance: Certain food-grade strong base anion exchange resin products, like Strong Base Anion Exchange Resin 201X4 FG, are designed for applications in food and beverage processing (e.g., sugar decolorization). These resins must comply with specific FDA regulations (e.g., 21 CFR 173.25) ensuring they are safe for use in processes that contact food.

- ASTM Standards: Industry-specific test methods published by ASTM International are often used to define and test physical and chemical properties of ion exchange resins, ensuring consistent and verifiable performance parameters.

Partnering with a supplier boasting decades of experience in the ion exchange industry and a portfolio of global clients further attests to their authoritativeness and trustworthiness. Access to detailed test data, performance validation reports, and transparent manufacturing practices are hallmarks of a credible vendor.

Trust & Support: FAQs, Lead Time, Warranty, and Customer Service

Building long-term partnerships in the B2B sector hinges on more than just product quality; it requires exceptional support and clear commitments. Our approach to service ensures complete customer satisfaction and operational continuity for your strong base anion resin systems.

Frequently Asked Questions (FAQs)

- Q: How often does a strong base anion resin need to be regenerated?

- A: Regeneration frequency depends on the feed water quality (anion load), flow rate, and desired effluent purity. High-quality resins are designed for longer service cycles. Our technical team can assist in calculating an optimal regeneration schedule based on your specific operational data.

- Q: What is the typical service life of a strong base anion resin?

- A: With proper operation, regeneration, and protection from fouling agents, a high-quality strong base resin can last between 3 to 7 years, and sometimes longer. Factors such as exposure to oxidants, organic fouling, and high temperatures can impact its lifespan. Regular resin analysis helps monitor performance.

- Q: Can strong base anion resins remove all types of anions?

- A: Strong base anion resins are highly effective at removing most common anions, including sulfates, chlorides, nitrates, bicarbonates, and silica. Their affinity order generally follows: Sulfate > Nitrate > Chloride > Bicarbonate. For highly selective removal of specific anions, specialized resins may be considered.

- Q: What are the storage requirements for strong base anion resins?

- A: Resins should be stored in their original sealed packaging in a cool, dry place, away from direct sunlight and freezing temperatures. Prolonged exposure to extreme conditions can affect performance. If stored in the Cl- form, ensure the resin does not dry out.

Lead Time and Fulfillment

We understand the critical nature of timely delivery. Our streamlined production and robust supply chain management ensure competitive lead times for all our strong base anion exchange resin products. Standard orders typically ship within 2-4 weeks, with expedited options available for urgent requirements. We maintain strategic stock levels and work closely with our logistics partners to ensure efficient and secure global delivery.

Warranty Commitments

All our strong base anion exchange resins are backed by a comprehensive product warranty, ensuring they meet specified technical parameters and are free from manufacturing defects for a defined period from the date of purchase. Our commitment to quality and performance is unwavering, providing peace of mind for your investment. Specific warranty terms are provided with each product quotation and order.

Dedicated Customer Support

Our team of experienced technical professionals is dedicated to providing unparalleled customer support. From initial consultation and resin selection to system optimization and troubleshooting, we offer expert guidance at every stage. We provide prompt responses to inquiries, on-site technical assistance where required, and comprehensive after-sales service to ensure the optimal and continuous operation of your ion exchange systems.

Conclusion

The efficacy of strong base anion exchange resins in industrial applications cannot be overstated. From ensuring ultrapure water for critical manufacturing processes to enabling efficient resource recovery and environmental compliance, these specialized polymeric materials are at the forefront of separation technology. Their robust chemical structure, high exchange capacity, and versatility make them an invaluable asset for industries striving for operational excellence and stringent purity standards. By partnering with knowledgeable manufacturers who prioritize quality, technical expertise, and tailored solutions, businesses can leverage the full potential of strong base anion resin technology to achieve sustainable and cost-effective purification outcomes.

References

- D. N. K. Murthy, Ion Exchange Resins: Types, Properties and Applications. Chemical Engineering Journal, 2018.

- M. J. R. Cantwell, Ion-Exchange Resins. Kirk-Othmer Encyclopedia of Chemical Technology, 2004.

- Ion Exchange for Drinking Water Applications. Water Quality Association, 2020.

- Annual Market Study: Global Ion Exchange Resins. Grand View Research, 2023.

- ASTM D2187 – 94(2018) Standard Test Methods for Physical and Chemical Properties of Particulate Ion-Exchange Resins. ASTM International.

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog