The IE Expo China stands as a preeminent annual event, a nexus for environmental solutions, cutting-edge technologies, and collaborative innovation across Asia. As a critical platform for addressing the planet’s most pressing environmental challenges, it consistently draws industry leaders, technology innovators, and B2B decision-makers eager to explore advancements in water, waste, air, and soil management. For sectors demanding exacting purity and separation—like the production of pharmaceutical intermediates and the processing of Plasma resin—IE Expo China offers unparalleled insights into the sophisticated technologies that underpin these vital industries. Central to many of these processes is the indispensable role of ion exchange resin, a technology that enables precision purification, separation, and resource recovery, directly impacting the quality and safety of critical products.

Industry Trend Spotlight: The Ascent of Ion Exchange Resins

Globally, there’s a palpable surge in demand for high-efficiency, selective, and regenerable ion exchange resin technologies. This isn’t just a fleeting trend; it’s a fundamental shift driven by escalating global challenges, from water scarcity to the need for ultra-pure materials in advanced manufacturing. Industries are increasingly recognizing the transformative power of these resins in achieving stringent purity standards and enhancing operational sustainability. The development of specialized resins for emerging applications—such as lithium extraction from brines, the intricate purification of pharmaceutical intermediates, and the advanced reclamation of industrial wastewater—is rapidly gaining traction and investment. Furthermore, the integration of process automation and digital technologies within water treatment systems is revolutionizing how these resins are utilized, optimized, and managed, leading to unprecedented levels of efficiency and reliability.

Market data underscores this dynamic growth: the global ion exchange resin market is projected to experience steady growth, with analysts forecasting a Compound Annual Growth Rate (CAGR) of 4-6% over the next five years. This expansion is propelled by several key factors: an intensifying global water crisis necessitating advanced treatment solutions, increasingly stringent environmental regulations pushing industries towards more sustainable practices, and the continuous expansion of industrial applications across diverse sectors. From power generation and chemical processing to food & beverage manufacturing and semiconductor production, the versatility and efficacy of anion exchange resin and cation exchange resins are unparalleled. Emerging focus areas include highly advanced water and wastewater treatment, critical resource recovery, sophisticated environmental monitoring, and the development of sustainable industrial processes that minimize waste and maximize efficiency. For B2B decision-makers, understanding these trajectories is crucial for strategic investment and future-proofing operations.

Profiles of Leading Manufacturers at IE Expo China

Hebei Lijiang Biotechnology Co.,Ltd. – Pioneering Purity Solutions

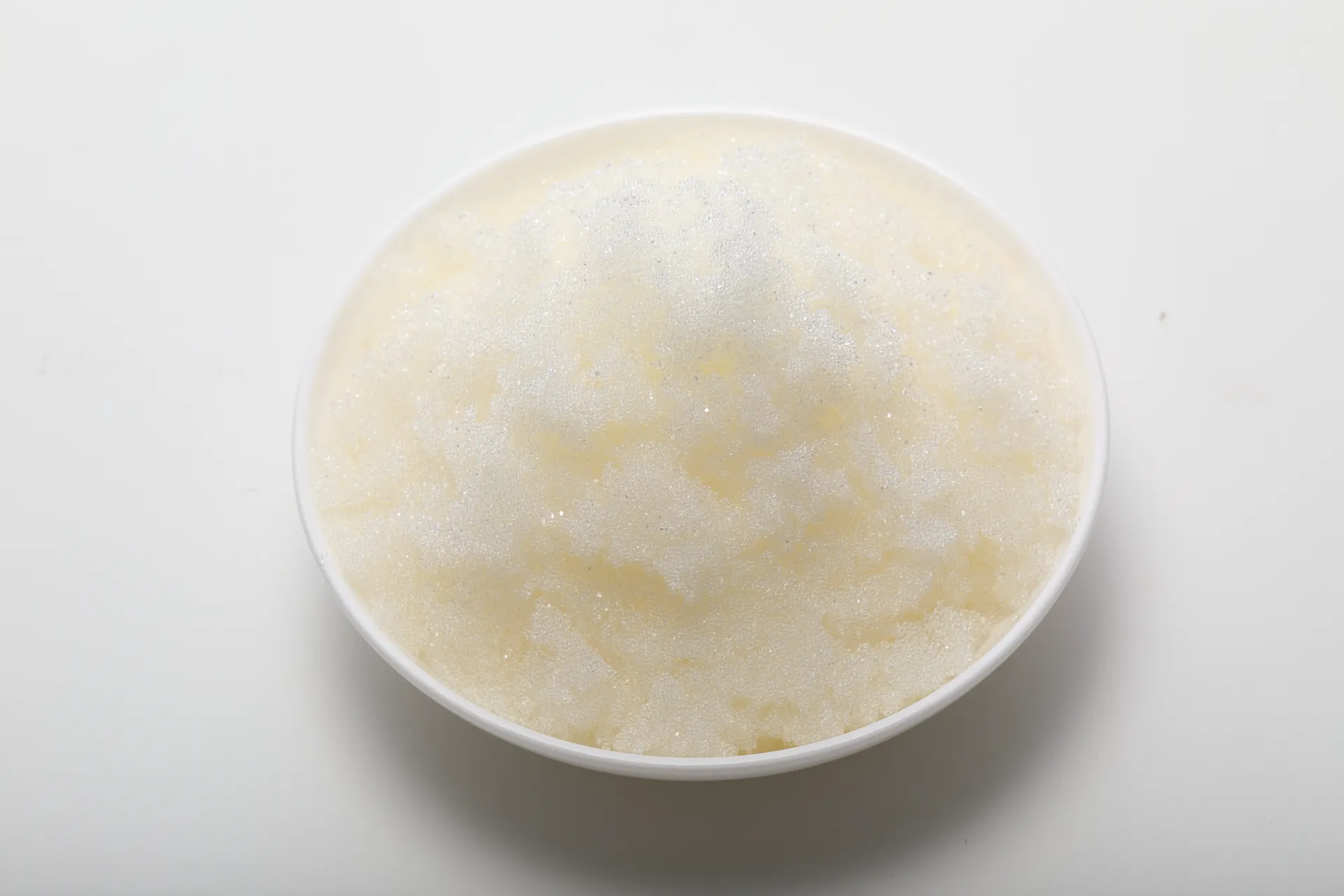

At the forefront of innovation in ion exchange resin technology is Hebei Lijiang Biotechnology Co.,Ltd. This esteemed Chinese manufacturer has carved out a significant niche through its specialization in a comprehensive range of high-quality resins, meticulously engineered to cater to diverse and critical applications. Their product portfolio spans solutions vital for large-scale industrial water treatment, the production of ultrapure water essential for semiconductor and pharmaceutical industries, sophisticated food processing, critical pharmaceutical purification (including the refinement of pharmaceutical intermediates), and advanced hydrometallurgy.

Hebei Lijiang Biotechnology Co.,Ltd. places a strong emphasis on product performance and delivering application-specific solutions. Their commitment to research and development ensures that their anion exchange resin and other specialized resins meet the most rigorous international standards, providing reliability and superior efficacy. For businesses seeking precision and efficiency in their purification and separation processes, exploring Hebei Lijiang’s offerings at IE Expo China presents a strategic opportunity to access cutting-edge technology and tailored expertise. Their resins are designed to optimize processes, reduce operational costs, and enhance the sustainability profile of their clients across various demanding industries.

Global Leaders in Ion Exchange Technology

Beyond the burgeoning local talent, IE Expo China also provides a stage for established global giants in the ion exchange resin sector. These companies continuously push the boundaries of technology, setting benchmarks for quality and innovation:

- DuPont Water Solutions: Renowned for their extensive portfolio including the acclaimed DOWEX™ exchange resin products, DuPont offers a vast array of high-performance ion exchange resins, reverse osmosis membranes, and ultrafiltration modules. Their solutions are critical for ultra-pure water production, demineralization, and selective separations in numerous industries, including power generation and industrial processing.

- Lanxess AG: A global leader in specialty chemicals, Lanxess provides a broad range of Lewatit® ion exchange resins. These resins are utilized in various applications, from water treatment and food & beverage processing to chemical catalysis and the purification of biopharmaceuticals. Their commitment to innovation drives highly efficient and sustainable solutions.

- Purolite (an Ecolab Company): Specializing in the development and manufacture of premium ion exchange resins, Purolite offers solutions for critical applications in life sciences, power generation, and general industrial sectors. Their resins are vital for chromatography, pharmaceutical purification, and high-purity water requirements, including applications for Plasma resin purification.

- Mitsubishi Chemical Corporation: With their DIAION™ and RELITE™ brands, Mitsubishi Chemical provides a comprehensive line of ion exchange resins used in water treatment, chemical processing, sugar refining, and more. Their advanced technologies support a wide array of industrial needs for separation and purification.

Market Outlook & Opportunities: Charting the Future

The future of the ion exchange resin market is characterized by rapid evolution and significant opportunities for B2B stakeholders. Upcoming trends indicate a sustained buyer demand for highly specialized resins that can tackle increasingly complex separation challenges with greater efficiency and lower environmental impact. This includes resins with enhanced selectivity for specific contaminants, higher regeneration efficiency to minimize chemical waste, and extended operational lifespans. The drive towards circular economy principles means that resource recovery, particularly in industrial wastewater and valuable metals extraction, will become a prime application area for these advanced materials.

Significant opportunities also lie in the convergence of ion exchange resin technology with broader industry megatrends:

- Automation: The integration of automated systems for resin management, backwashing, regeneration, and performance monitoring will become standard, reducing manual intervention and optimizing process control.

- Smart Manufacturing (Industry 4.0): Predictive analytics, IoT sensors, and AI-driven optimization will enhance the efficiency and longevity of ion exchange resin systems, offering real-time insights into performance and enabling proactive maintenance.

- Sustainability: The demand for eco-friendly resins, manufacturing processes with lower carbon footprints, and solutions that facilitate greater water reuse and waste minimization will dominate procurement decisions. This includes the development of more durable resins that reduce the frequency of replacement and disposal.

These trends highlight a clear path for businesses: those that invest in advanced ion exchange resin technologies and integrate them with smart, sustainable operational frameworks will secure a competitive advantage in a rapidly evolving market.

Buyer/Business Takeaways: Strategic Investments in Purity

For B2B decision-makers, understanding the critical role of ion exchange resin technology is more important than ever. Investing in high-quality resins, especially those tailored for demanding applications such as the purification of pharmaceutical intermediates or the processing of Plasma resin, is not merely an operational expenditure but a strategic imperative. These investments directly impact product quality, compliance with regulatory standards, operational efficiency, and ultimately, market competitiveness. Superior anion exchange resin and cation exchange resin systems can lead to reduced waste, lower energy consumption, and enhanced product yields, translating into significant long-term savings and environmental benefits.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly research potential partners, examining their certifications, quality control processes, R&D capabilities, and track record. Events like IE Expo China offer excellent opportunities for face-to-face interactions.

- Focus on Application-Specific Expertise: Look for manufacturers who demonstrate deep understanding of your specific application requirements. For instance, in pharmaceutical purification, specialized ion exchange resin knowledge is paramount.

- Prioritize Technical Support & After-Sales Service: A strong partnership includes ongoing technical support, troubleshooting, and continuous optimization of resin performance.

- Seek Innovation & Customization: The best partners are those willing to innovate and customize solutions for unique challenges, rather than offering one-size-fits-all products.

Future-Proof Strategies:

- Embrace Digital Transformation: Integrate smart monitoring and control systems for your ion exchange resin processes to enhance efficiency and predictability.

- Invest in Sustainable Solutions: Opt for resins that offer longer lifespans, greater regenerability, and are manufactured with environmentally conscious practices. This aligns with global sustainability goals and future regulatory landscapes.

- Diversify Supply Chains: While focusing on key partners, consider diversifying your ion exchange resin supply chain to mitigate risks and ensure continuity.

Conclusion: IE Expo China and the Future of Purity

IE Expo China serves as an invaluable barometer and accelerator for the global environmental technology sector. It uniquely brings together the innovation and manufacturing prowess of China with the intricate demands of international industries. For the ion exchange resin market, including its vital applications in pharmaceutical intermediates and Plasma resin processing, the expo is more than just a trade show; it’s a dynamic forum shaping future collaborations, technological advancements, and sustainable practices. The insights gained and partnerships forged at this event are instrumental in driving efficiency, purity, and environmental responsibility across countless industries worldwide.

As the demand for cleaner water, purer products, and more sustainable industrial operations continues to grow, the role of advanced ion exchange resin technologies will only become more pronounced. Manufacturers like Hebei Lijiang Biotechnology Co.,Ltd., with their dedication to quality and application-specific solutions, are pivotal in meeting these evolving needs.

Ready to explore cutting-edge anion exchange resin technologies for your specific applications?

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog