Oil Resin: the quiet workhorse behind flexible, water‑resistant coatings

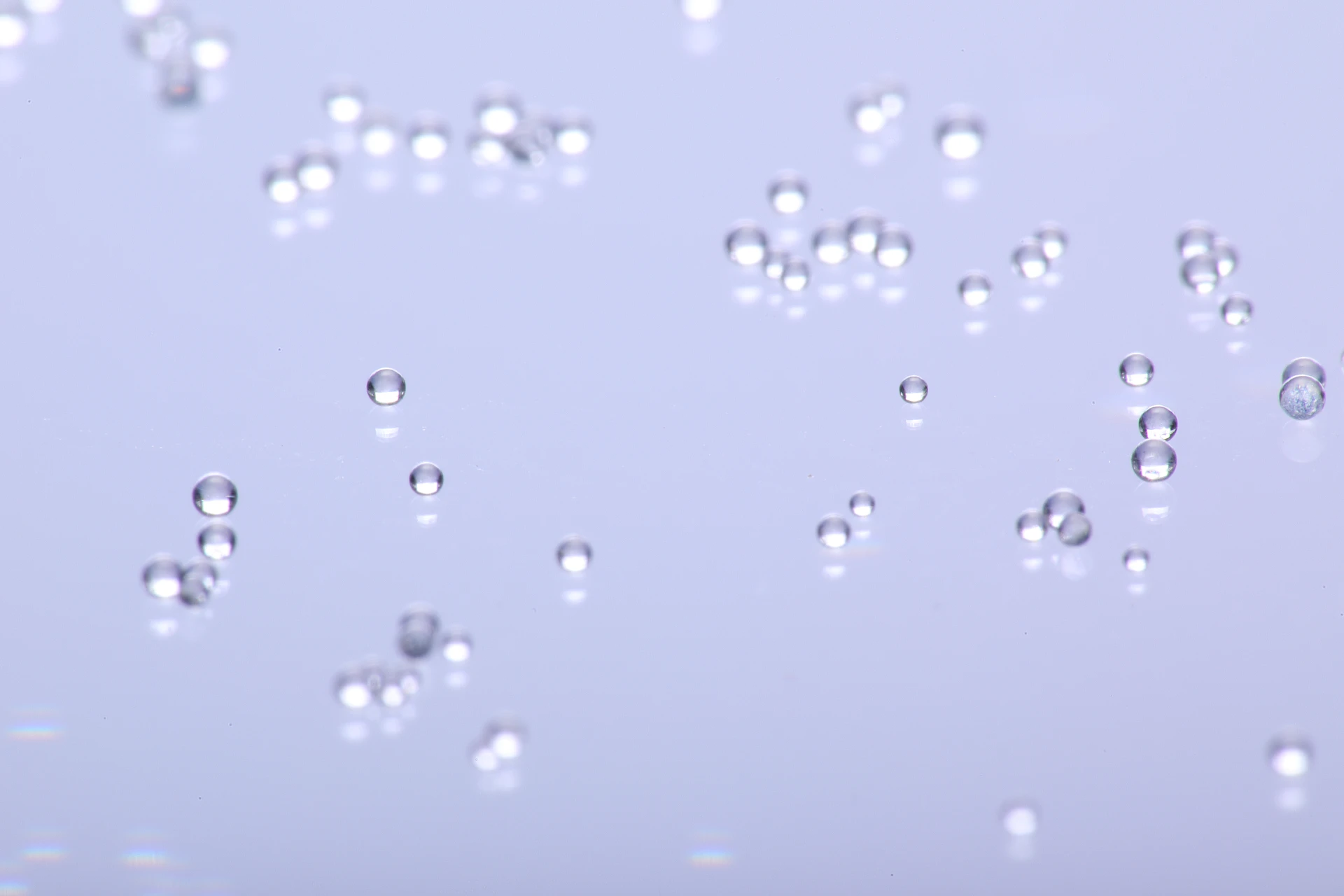

I’ve been tracking the evolution of special resin for years, and, to be honest, it keeps sneaking into more applications than you might expect. Oil-modified systems—like this one—bridge a tricky gap: the flexibility of oils with the adhesion and chemical resistance of resin backbones. Many customers say the difference shows up on humid days or after a hard winter, when films still hold, edges don’t lift, and water beading remains consistent.

What it is and why it matters

Oil Resin is a high‑performance natural or synthetic resin modified with selected oils (think tung, linseed, sometimes soybean) to enhance flexibility, adhesion, and water resistance. In fact, the oil modification tunes crosslink density—so the dried film can flex with substrates, not fight them. That’s why formulators in protective coatings, inks, and pressure‑sensitive adhesives keep shortlisting special resin when thermal cycling or damp exposure is in the spec.

Industry trends I’m seeing

- Shift to low‑VOC and higher‑solids systems; special resin grades tailored for exempt solvents.

- Bio‑based oil feeds gaining share (≈30–50% bio‑content in some lines).

- Hybridization with phenolic or acrylic resins for faster cure and harder films.

- Marine and packaging growth, especially where moisture and flexibility collide.

Typical product specifications

| Property | Typical Value (≈) | Test/Method |

|---|---|---|

| Softening Point (Ring & Ball) | 85–110 °C | ASTM E28 |

| Viscosity @25 °C | 1,000–3,500 mPa·s | Brookfield |

| Acid Value | 8–20 mg KOH/g | ASTM D974 |

| Color (Gardner) | 3–6 | ASTM D1544 |

| Water Absorption, 24 h | ≤0.5% | ASTM D570 |

Values are typical; real‑world use may vary by solvent cut, oil type, and cure schedule.

Process flow (how it’s made well)

Raw materials: rosin/synthetic resin backbone + selected oils + catalysts. Methods: controlled esterification → oil modification → polymerization/advancement → vacuum stripping (reduce volatiles) → filtration. QC: softening point (ASTM E28), acid value, viscosity, color, and accelerated humidity/UV. Service life: around 5–8 years outdoors (coating context), 10+ years indoors, assuming proper formulation and film thickness.

Where it shines

- Protective and marine coatings needing adhesion to steel/galvanized with good salt‑spray resistance.

- Printing inks and overprint varnishes that must remain flexible on films.

- Adhesives and road‑marking paints—fast wet‑out, solid tack, and weatherability.

Vendor snapshot and customization

| Vendor | Origin | Customization | Certs/Compliance |

|---|---|---|---|

| Liji Resin (Oil Resin) | NO.2 East Jianshe Road, High‑Tech Industrial Development South Zone, Wei County, Xingtai, Hebei, China | Oil type, softening point, solvent cut, color | ISO management systems, REACH/RoHS readiness |

| Supplier A | EU | Color and viscosity focus | REACH |

| Supplier B | US | High‑solids grades | RoHS |

Customization notes: you can dial oil length for flexibility, use hybrid backbones for block resistance, and tweak solvent systems for faster flash. It seems that tighter acid value control helps wet‑adhesion during crosshatch tests.

Testing, data, and standards

- Mandrel bend (ASTM D522): passes 3 mm after 7‑day cure at 25 °C.

- Adhesion (ASTM D3359): 4B–5B on properly prepped steel.

- Water uptake (ASTM D570): ≤0.5% at 24 h; still respectable at 72 h.

- Salt spray (ASTM B117): 500–1,000 h with compatible anticorrosive pigments.

Quick case study

A Southeast Asia marina needed a tough deck coating. Swapping in special resin raised adhesion by ≈25% (crosshatch 3B → 5B) and cut blistering after 800 h salt spray to “few, size 2” from “medium, size 6”. The maintenance window stretched from yearly to every 24–30 months. Not bad.

What users say

“Flows nicely, bites into galvanized without the usual drama.” “Dry‑to‑touch is predictable—less rework.” Feedback like this is common when special resin replaces brittle binders in damp or flexible service.

Compliance: ISO 9001 management systems, typical REACH and RoHS considerations; food‑contact variants may be engineered to align with FDA 21 CFR 175.300—check your regulatory team first.

Authoritative references

- ASTM E28 – Standard Test Methods for Softening Point of Resins by Ring‑and‑Ball Apparatus.

- ASTM D570 – Standard Test Method for Water Absorption of Plastics.

- ASTM D522 – Standard Test Methods for Mandrel Bend of Attached Organic Coatings.

- ISO 9001 – Quality management systems — Requirements.

- Regulation (EC) No 1907/2006 (REACH) – Registration, Evaluation, Authorisation and Restriction of Chemicals.

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog