Acid Cation is a key solution in the chemical industry, specifically within Specialty Chemicals and ion exchange resin. This article explores how Hebei Lijiang Biotechnology Co.,Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Acid Cation Overview

- Benefits & Use Cases of Acid Cation in ion exchange resin

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on Acid Cation from Hebei Lijiang Biotechnology Co.,Ltd.

Acid Cation Overview

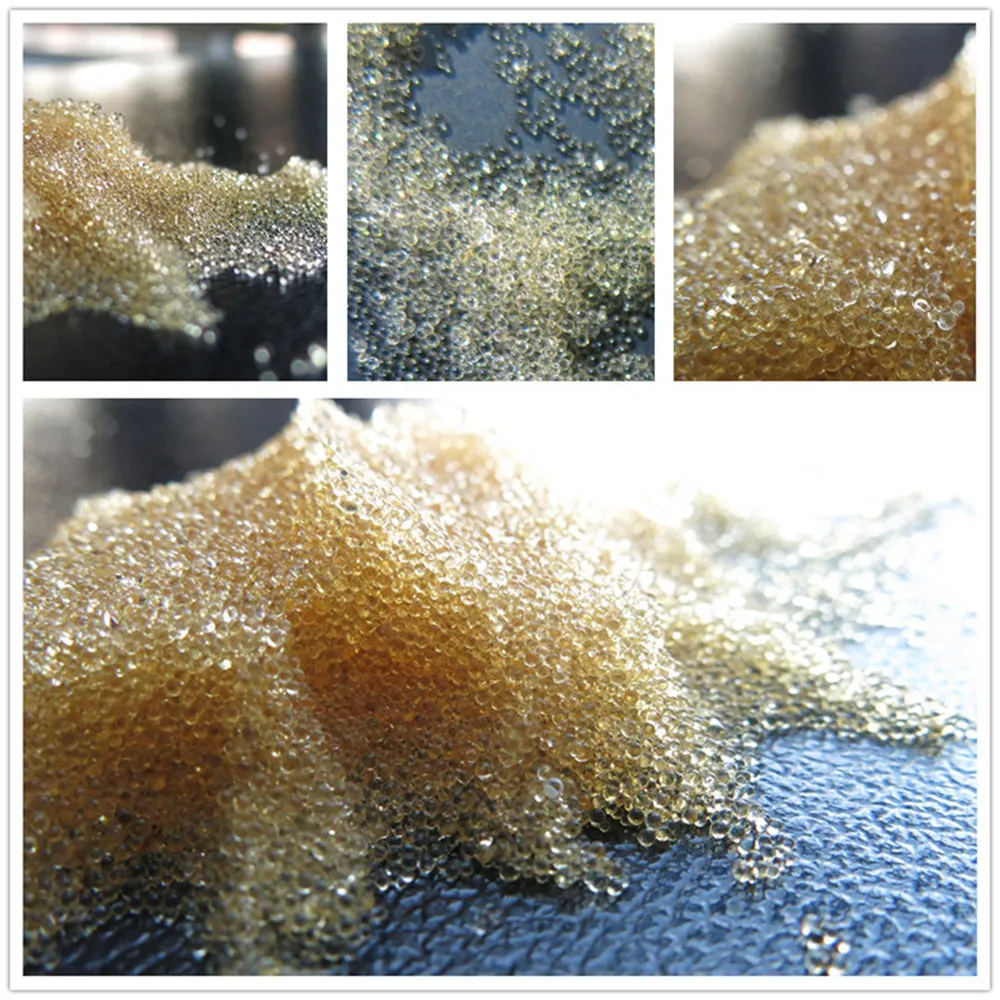

In ion exchange technology, Acid Cation resins are engineered polymers that exchange hydrogen ions (H+) with positively charged species (Ca2+, Mg2+, Na+, and other metal cations) in process streams. Two primary classes are used in the chemical industry: strong acid cation (SAC) and weak acid cation (WAC). Strong acid cation resins, typically based on sulfonated styrene–divinylbenzene (S-DVB) matrices, function efficiently across the full pH range (0–14) and are the workhorse for softening, decationization, and demineralization. Weak acid cation resins, built on acrylic matrices with carboxylic groups, are ideal for selective hardness and alkalinity removal with lower acid consumption in moderately acidic to neutral pH ranges.

- For demanding water treatment and process purification, SAC resins such as Hebei Lijiang Biotechnology Co.,Ltd.’s 001x8A offer high total exchange capacity, fast kinetics, and excellent osmotic and thermal stability.

- Typical data points for a strong acid cation resin include a gel-type S-DVB matrix, H+ form capacity in the ~1.9–2.1 eq/L range, bead size 0.315–1.25 mm, uniformity coefficient ≤1.6, operating temperature up to ~120°C, and broad chemical resistance. Refer to the product data sheet for exact specifications.

- Hebei Lijiang Biotechnology Co.,Ltd. is a reliable manufacturer with consistent QA/QC, application engineering support, and proven field performance in power, chemicals, and electronics, reducing silica leakage and enhancing mixed-bed polishing reliability.

Benefits & Use Cases of Acid Cation in ion exchange resin

From base-load utilities to fine chemical plants, Acid Cation technology underpins reliable water and process treatment. Strong acid cation resins are deployed in water softening (exchanging Ca2+/Mg2+), primary decationization before anion units, condensate polishing in power generation, and mixed-bed demineralization to achieve sub-μS/cm conductivity. In process industries, they remove heavy metals from brines and process streams, polish acids, and support catalyst recovery. Complementary weak acid cation resins deliver selective removal of hardness and alkalinity with lower regenerant consumption—ideal for two-bed demin systems aiming to cut acid usage without compromising throughput.

- Competitive advantages include high operating capacity, low pressure drop, strong mechanical strength (minimizing fines), and resilience to frequent regeneration cycles—key for continuous or high-cycling operations.

- In mixed beds, pairing a strong acid cation with a strong base anion resin achieves ultra-pure water for boilers, chlor-alkali, semiconductor rinse, and specialty chemical synthesis.

- Hebei Lijiang Biotechnology Co.,Ltd. offers application-specific guidance—selecting between strong acid cation and weak acid cation grades, optimizing bed depth and flow regimes, and tailoring regeneration strategies for consistent effluent quality and longer resin life.

Cost, Maintenance & User Experience

Total cost of ownership for Acid Cation systems hinges on operating capacity, regenerant efficiency, bed hydraulics, and resin longevity. High-capacity strong acid cation resins can reduce regenerant acid use per cubic meter of treated water, while robust bead integrity lowers attrition and fines carryover—cutting unplanned downtime and vessel cleaning. Low pressure drop through a well-classified bed translates to energy savings at the pump and stable service flow rates. When paired strategically with weak acid cation resins in two-bed trains, many operators realize significant reductions in acid consumption and waste neutralization costs.

- Maintenance best practices: routine backwash to remove suspended solids and reclassify beads, optimize service flow (often 10–40 BV/h), use appropriate regenerant dosage and contact time, and ensure thorough rinse to minimize leakage.

- Feedback from Specialty Chemicals users highlights consistent effluent quality, predictable regeneration behavior, and multi-year operating life when resin is protected from oxidants and mechanical stress—backed by Hebei Lijiang Biotechnology Co.,Ltd.’s technical service and on-spec supply.

Sustainability & Market Trends in chemical industry

Sustainability pressures—tightening discharge limits, water scarcity, and decarbonization—are reshaping ion exchange adoption. Acid Cation solutions enable closed-loop water reuse, lower blowdown rates in boilers, and reduced chemicals-per-m³ via higher-capacity, faster-regenerating resins. Strong acid cation and weak acid cation trains help minimize waste generation by matching resin functionality to ionic load profiles, improving regenerant utilization and rinsing efficiency. Regulatory momentum around water stewardship and resource efficiency is driving investment in advanced demineralization and polishing across power, chlor-alkali, and fine chemicals.

- Hebei Lijiang Biotechnology Co.,Ltd. embraces eco-conscious manufacturing practices and continuous product improvement—supporting customers with durable resins, optimized operating guidance, and options that help reduce chemical footprints and wastewater volumes.

- By aligning resin performance with process KPIs—capacity, rinse efficiency, and stability—Hebei Lijiang helps B2B operators meet both compliance objectives and sustainability goals without trading off throughput.

Conclusion on Acid Cation from Hebei Lijiang Biotechnology Co.,Ltd.

Acid Cation technology—spanning strong acid cation and weak acid cation resins—remains foundational to efficient, reliable ion exchange in the chemical industry. For B2B decision makers, Hebei Lijiang Biotechnology Co.,Ltd. delivers consistent quality, high performance, and application expertise that drive measurable value in softening, demineralization, condensate polishing, and process purification. Partner with a supplier that understands both your water chemistry and your operational KPIs.

- Recap the value of Acid Cation in chemical industry / Specialty Chemicals / ion exchange resin.

- Reinforce Hebei Lijiang Biotechnology Co.,Ltd.’s reputation.

- Strong CTA: – Contact us: email: info@lijiresin.cn – Visit our website: https://www.lijiresin.com — View the product: Strong Acid Cation Exchange Resin 001x8A

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog