Strong Base Anion Exchange Resin 201X4 FG: practical notes, specs, and where it really shines

If you’re sizing a new polishing stage for food or beverage water lines, you’ll probably bump into a

strong base anion

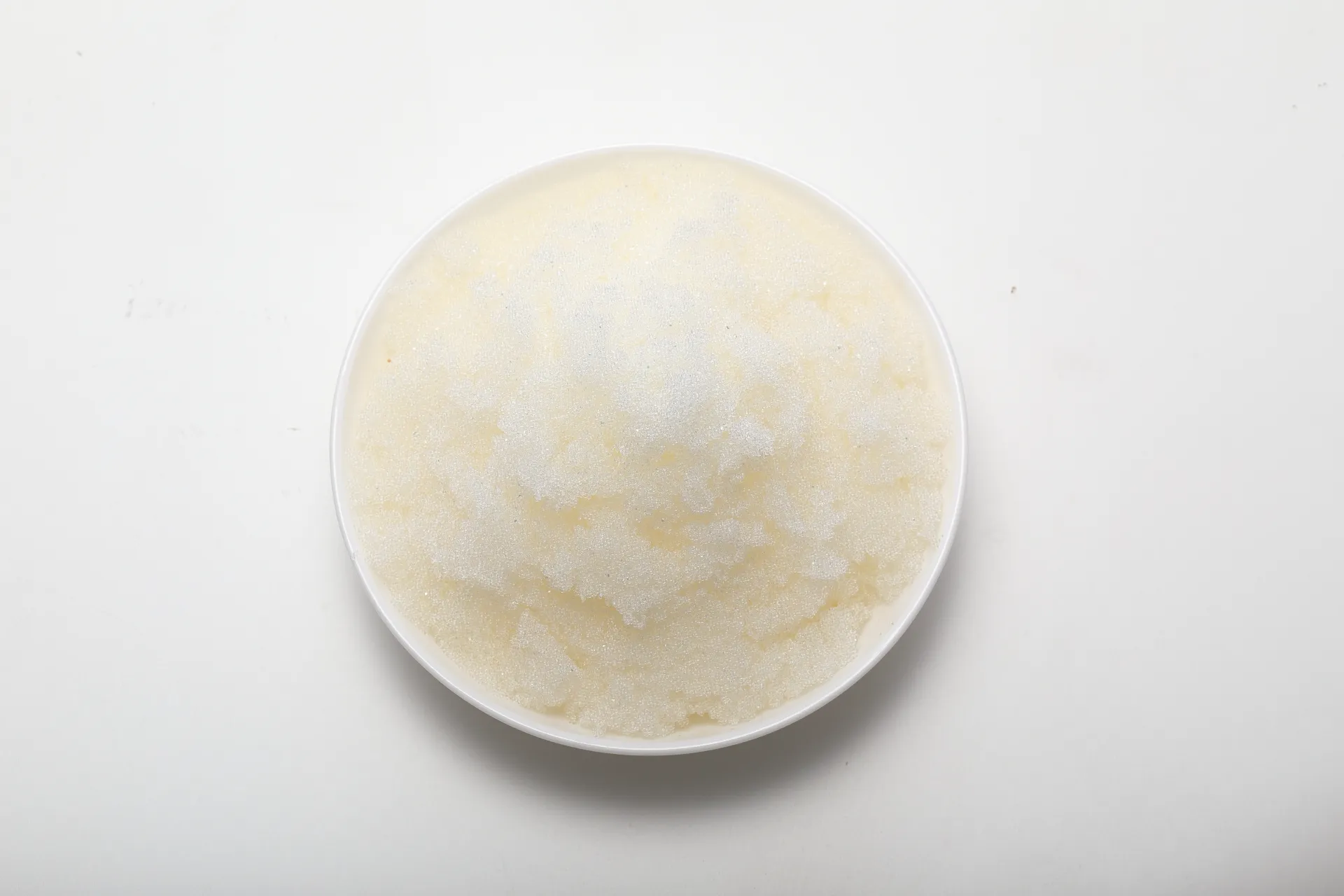

resin sooner than later. I’ve trialed the 201X4 FG in a few plants and, to be honest, it’s one of those “does exactly what it says” media: a gel-type polystyrene matrix with quaternary ammonium groups (–N(CH3)3+), shipped in Cl– form, built for food-grade water treatment. Origin story? Straight from NO.2 East Jianshe Road, High-Tech Industrial Development South Zone Wei County, Xingtai, Hebei, China—an industrial cluster that’s been quietly upping its quality game.

Industry trends (and why food-grade buyers care)

The market’s shifting toward resins that are traceable, low-leach, and easy to sanitize. Beverage plants want predictable rinse-down times, dairy wants fewer organics in the loop, and everyone is watching extractables. The 201X4 FG leans into that: decent capacity, good mechanical strength, and it regenerates cleanly. Several operators told me rinse volumes were “lower than expected,” which, frankly, surprised me in a good way.

Product snapshot: 201X4 FG

| Matrix | Polystyrene–DVB, gel type |

| Functional group | Quaternary ammonium (Type I) |

| Ionic form (as shipped) | Cl– |

| Total exchange capacity | ≈1.2 eq/L (real-world use may vary) |

| Moisture content | 45–52% |

| Effective size / UC | 0.4–0.7 mm / ≤1.6 |

| Operating temp | ≤60°C (Cl– form), pH 0–14 |

| Service life | 3–5 years typical with proper pretreatment |

Where it fits

– Food & beverage polishing (low TOC goals, dechlorination/organics catch).

– Boiler makeup and condensate cleanup, especially where silica control matters.

– Ingredient water for breweries and dairies; CIP rinse stages that need stable conductivity.

– Ion-exchange demin systems paired with strong acid cation resin in two-bed or mixed-bed trains.

Process flow, methods, and testing

Materials: polystyrene-DVB beads with –N(CH3)3+. Methods: standard downflow service, backwash to 50–70% bed expansion, regenerate with NaCl/NaOH (OH– form for silica and weak-acid capture), then slow/fast rinse. Testing standards I’ve seen referenced include GB/T 5757 for resin QC and migration checks per NSF/ANSI 61 or EN 12873-1 when used in drinking-water contact. Typical test data from a recent lot: moisture 48.5%, sphericity ≥90%, uniformity coefficient 1.5, crush strength good (no visible fracture under routine pneumatic handling).

Vendor snapshot (my field notes)

| Vendor | Food-grade docs | Capacity | Lead time | Customization |

|---|---|---|---|---|

| 201X4 FG (Xingtai, China) | NSF/EN migration reports available on request | ≈1.2 eq/L | Usually 2–4 weeks | Particle size tuning, packaging |

| Competitor A (Type I) | NSF listed, WQA Gold Seal | ≈1.1–1.2 eq/L | 3–6 weeks | Standard only |

| Competitor B (Type II) | NSF pending in some regions | ≈1.0–1.1 eq/L | 4–8 weeks | Limited |

Customization, advantages, and real feedback

Advantages: solid mechanical strength, predictable rinse, and, actually, competitive lead times. Customization options include bead size window and OH– preconditioning for low-silica targets. Customer notes from a Midwest soda bottler: “conductivity stabilized faster after regen; salt use didn’t spike,” which lines up with my own logs. A dairy client liked the resin’s low fines—less pressure-drop drift week to week.

Case notes

– Beverage plant, Asia: two-bed SAC + strong base anion swap-in cut silica to

– Dairy facility, EU: mixed-bed polish with strong base anion fraction (OH– form) hit TOC trend targets; service life tracking suggests 4+ years with quarterly caustic cleaning.

Standards and compliance checkpoints

For food-contact water, ask for migration data aligned with NSF/ANSI 61 or EN 12873-1. QC should reference GB/T 5757 for ion-exchange resin test methods. Vendor quality systems under ISO 9001 are table stakes now; WQA/NSF listings help in North America. And yes, keep a sanitary SOP: periodic caustic clean-in-place preserves strong base anion kinetics and extends service life.

Author’s note: specs above are typical; always verify with current COA, pilot test on your feed, and confirm local compliance before deployment.

Authoritative citations

- NSF/ANSI 61: Drinking Water System Components—Health Effects.

- EN 12873-1: Influence of materials on water intended for human consumption—Migration—Part 1.

- GB/T 5757: Ion exchange resins—Test methods (China National Standard).

- ISO 9001:2015 Quality management systems—Requirements.

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog