Advanced Ion Exchange Resin Solutions for Industrial Applications

In the intricate landscape of industrial processing, the purity and quality of water and other liquid streams are paramount. At the heart of achieving these stringent standards lies advanced ion exchange resin technology. These sophisticated polymeric materials are engineered to facilitate the reversible interchange of ions between an insoluble solid phase (the resin) and a liquid phase (the surrounding solution), making them indispensable across a multitude of B2B sectors, from critical water treatment to specialized chemical separations.

The demand for high-performance ion exchange resin solutions continues to grow, driven by escalating environmental regulations, the need for enhanced process efficiency, and the increasing scarcity of potable water sources. Industries are actively seeking resins that offer not only superior selectivity and capacity but also exceptional mechanical and chemical stability, ensuring long service life and cost-effectiveness. The market is trending towards more specialized resins, including highly selective chelating resins and advanced types designed for challenging applications such as heavy metal removal, pharmaceutical purification, and selective contaminant extraction. Furthermore, advancements in manufacturing processes are leading to resins with tighter particle size distribution, improving kinetics and regenerant efficiency. This evolution underscores the critical role of these materials in modern industrial operations.

Manufacturing Process of Ion Exchange Resins: From Monomer to Advanced Polymer

The production of a high-quality ion exchange resin is a multi-stage, precision-engineered process that demands rigorous control over chemical reactions and physical properties. Unlike traditional mechanical components that involve casting or forging, resin manufacturing focuses on chemical synthesis and polymerization.

- Monomer Preparation: The foundation of most commercial ion exchange resins, particularly strong base anion resins like our 201X8, begins with primary monomers such as styrene and divinylbenzene (DVB). DVB acts as a cross-linking agent, providing the polymer matrix with mechanical strength and insolubility. The precise ratio of DVB to styrene dictates the resin’s porosity, swelling characteristics, and mechanical integrity, directly influencing its service life under various industrial conditions.

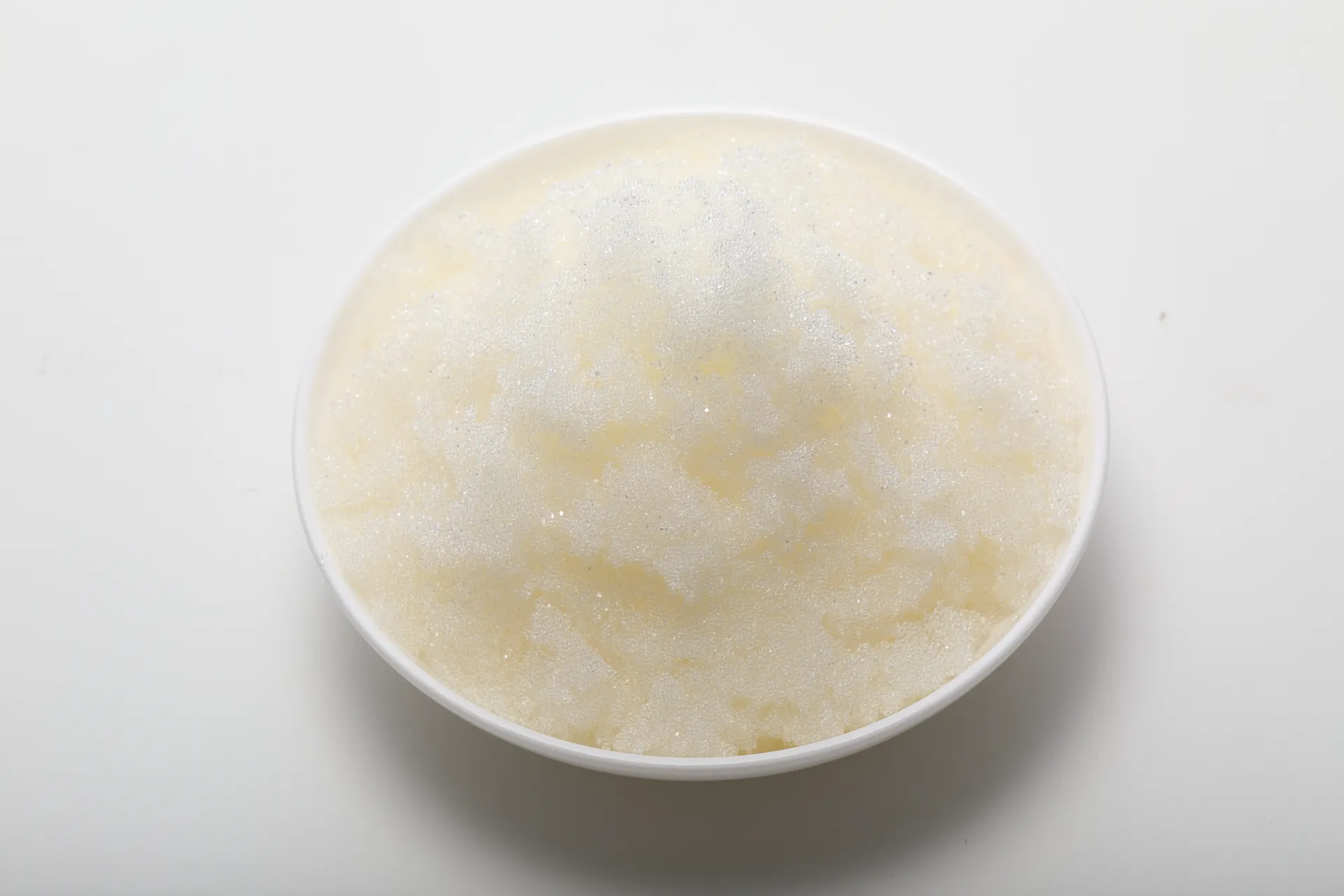

- Suspension Polymerization: Monomers are suspended in an aqueous phase with initiators and stabilizers. Under carefully controlled temperature and agitation, the monomers polymerize into spherical beads. This process is crucial for achieving uniform particle size distribution, which is vital for optimal flow rates and pressure drop in resin columns.

- Functionalization: This is the most critical step in determining the resin’s ion exchange properties. For a strong base anion exchange resin like 201X8, the styrene-DVB copolymer beads undergo chloromethylation, where chloromethyl groups are introduced onto the aromatic rings. Subsequently, these chloromethyl groups react with tertiary amines (e.g., trimethylamine) in an amination step to form quaternary ammonium functional groups. These groups are responsible for the resin’s strong basicity and its ability to capture anions like sulfates, nitrates, and chlorides even at high pH.

- Washing and Purification: The functionalized resin beads are thoroughly washed to remove residual monomers, unreacted chemicals, and byproducts. This step ensures product purity and prevents contamination in downstream applications.

- Sizing and Quality Control: The final product is sieved to achieve a specific particle size range. Each batch undergoes rigorous testing to meet international standards such as ISO 9001 and ANSI/AWWA, ensuring consistent quality, capacity, moisture content, osmotic stability, and mechanical strength. This guarantees a predictable service life, typically ranging from 5 to 10 years, depending on the application and operating conditions.

Target industries benefiting from these highly engineered resins include petrochemicals (for acid removal and condensate polishing), metallurgy (for precious metal recovery and effluent treatment), and water supply & drainage (for demineralization and softening). In these scenarios, the advanced manufacturing processes contribute to energy saving through efficient regeneration cycles and provide superior corrosion resistance by effectively removing corrosive ions from process streams.

Technical Specifications: Strong Base Anion Exchange Resin 201X8

Understanding the detailed technical specifications of a strong base anion exchange resin is crucial for effective system design and optimal performance. Our Strong Base Anion Exchange Resin 201X8 exemplifies a macroporous Type I resin, renowned for its excellent physical and chemical stability, high operating capacity, and superior resistance to organic fouling.

Its macroporous structure provides a larger surface area for ion exchange, facilitating better kinetics and making it particularly suitable for treating waters with high organic content or for applications requiring robust performance under varied conditions. The quaternary ammonium functional groups ensure strong basicity, allowing for efficient removal of weakly acidic ions (like silica and carbon dioxide) in addition to strong acid anions.

Product Specification Table: Strong Base Anion Exchange Resin 201X8

| Characteristic | Specification |

|---|---|

| Polymer Matrix Structure | Macroporous Polystyrene Divinylbenzene (DVB) |

| Functional Group | Quaternary Ammonium, Type I |

| Ionic Form (as shipped) | Cl- (Chloride) |

| Total Exchange Capacity (min.) | 1.0 meq/ml (Cl- form) |

| Moisture Retention | 50 – 55% |

| Effective Size | 0.4 – 0.7 mm |

| Uniformity Coefficient (max.) | 1.6 |

| Specific Gravity (approx.) | 1.07 g/ml |

| Shipping Weight (approx.) | 670 – 710 g/l |

| Operating pH Range | 0 – 14 |

| Maximum Operating Temperature | 80°C (175°F) |

These parameters are critical for engineers designing or optimizing ion exchange resin systems. High total exchange capacity ensures prolonged service cycles between regenerations, leading to reduced chemical consumption and operational costs. The specific particle size and uniformity coefficient are crucial for minimizing pressure drop and preventing channeling, thereby enhancing overall system efficiency. The broad operating pH range and high-temperature tolerance signify the resin’s robustness in demanding industrial environments.

Application Scenarios and Technical Advantages

The versatility of ion exchange resins, particularly strong base anion types, allows for their application across a diverse range of critical industrial processes, delivering significant technical and economic advantages.

- Water Demineralization: In power generation, microelectronics, and pharmaceuticals, ultra-pure water is essential. Strong base anion exchange resins, often used in conjunction with cation exchange resins, achieve virtually complete removal of dissolved solids (anions like chlorides, sulfates, nitrates, and even silica), ensuring the highest water quality for boiler feed, process rinse water, and pharmaceutical formulations. This directly prevents scaling, corrosion, and product contamination.

- Condensate Polishing: In thermal power plants, condensate polishing units utilize mixed beds of strong acid cation and strong base anion exchange resins to remove trace contaminants (e.g., iron, copper, silica) from condensed steam. This application is crucial for protecting high-pressure boilers and turbines from corrosion and deposits, leading to enhanced energy saving and prolonged asset life.

- Effluent Treatment: Industries such as metallurgy and electroplating often generate wastewater containing heavy metals and other toxic anions. Specialized ion exchange resins can selectively remove these contaminants, helping companies meet strict environmental discharge regulations and recover valuable resources, thereby demonstrating robust corrosion resistance management in effluent streams.

- Chemical Process & Purification: In the petrochemical industry, resins are used for acid removal from organic streams, catalyst recovery, and product purification. For instance, strong base anion resins can remove chlorinated organics or unwanted acids from hydrocarbon streams, improving product quality and process efficiency.

- Food and Beverage Industry: Resins are employed for de-ashing sugar solutions, demineralizing whey, and removing unwanted color bodies or bitter compounds from fruit juices, ensuring product quality and stability while adhering to FDA (Food and Drug Administration) guidelines where applicable.

The technical advantages are manifold: significant energy saving through optimized regeneration cycles, superior corrosion resistance due to effective ion removal, high efficiency in contaminant reduction, and long operational service life resulting in lower total cost of ownership.

Vendor Comparison: Strong Base Anion Exchange Resins (201X8 vs. Dowex Equivalents)

When selecting an anion exchange resin, B2B decision-makers often evaluate products from various reputable manufacturers. While brands like Dowex (a popular line of ion exchange resins) are well-known, understanding the comparative advantages of alternatives like our Strong Base Anion Exchange Resin 201X8 is essential for optimal procurement.

Our 201X8 resin is engineered to offer comparable or superior performance to leading industry equivalents, particularly in terms of operational capacity, physical stability, and resistance to organic fouling. The macroporous structure of 201X8 provides enhanced kinetic performance and regenerant efficiency, which can lead to lower operational expenditures compared to some gel-type resins.

Product Comparison Table: Strong Base Anion Resin (Lijiresin 201X8 vs. Generic Dowex SBA Equivalent)

| Characteristic | Lijiresin 201X8 | Generic Dowex SBA (Type I, Macroporous) Equivalent |

|---|---|---|

| Polymer Matrix | Macroporous Styrene-DVB | Macroporous Styrene-DVB |

| Functional Group | Quaternary Ammonium (Type I) | Quaternary Ammonium (Type I) |

| Total Capacity (meq/ml) | ≥ 1.0 | Typical 0.9 – 1.1 |

| Moisture Retention (%) | 50 – 55 | 48 – 58 |

| Operating Temp. (°C) | Max. 80 | Max. 85 |

| Resistance to Organic Fouling | Excellent (Macroporous) | Good to Excellent (Macroporous) |

| Osmotic & Physical Stability | Very High | High |

This comparison highlights that Lijiresin 201X8 offers competitive specifications, often with an advantage in specific areas such as osmotic stability, which translates to a longer service life and reduced replacement frequencies. Our commitment to stringent quality control, backed by ISO certifications, ensures that our anion exchange resin consistently meets or exceeds performance expectations, providing a reliable and cost-effective solution for industrial demineralization and purification needs.

Customized Solutions and Application Case Studies

Recognizing that no two industrial processes are identical, we specialize in providing customized ion exchange resin solutions. Our engineering team collaborates closely with clients to understand their unique operational challenges, water chemistry, and performance requirements. This involves selecting the optimal resin type, customizing particle size distribution for specific flow dynamics, and advising on system design and regeneration protocols to maximize efficiency and longevity. Whether it’s developing a specialized resin for selective contaminant removal or optimizing an existing system for higher throughput, our expertise ensures a tailored approach.

Case Study 1: Ultra-Pure Water for a Pharmaceutical Manufacturer

A leading pharmaceutical client required an upgrade to their water purification system to meet stricter USP (United States Pharmacopeia) standards for purified water used in injectable solutions. Their existing system struggled with consistent silica and TOC (Total Organic Carbon) removal, leading to increased regeneration frequency and operational downtime.

- Challenge: Achieve consistently low conductivity (< 0.1 µS/cm) and TOC (< 50 ppb) with reduced regenerant consumption.

- Solution: We recommended a combination of our Strong Acid Cation Resin and Strong Base Anion Exchange Resin 201X8 in a mixed-bed configuration. The macroporous structure of 201X8 was particularly beneficial for enhanced silica removal kinetics and improved resistance to organic fouling from incoming feed water.

- Results: Post-implementation, the client observed a 40% reduction in silica leakage and a 25% decrease in overall regenerant chemical usage, leading to significant cost savings and compliance with the most stringent pharmaceutical water quality standards. The service life of the resin beds also extended by 18 months, reducing maintenance frequency. Customer feedback highlighted the resin’s robust performance and the comprehensive technical support provided.

Case Study 2: Chromium Removal in Metal Finishing Effluent

A metal finishing company faced significant challenges in complying with discharge limits for hexavalent chromium (Cr(VI)) in their wastewater. Traditional chemical precipitation methods were costly and often failed to achieve the required ppb levels.

- Challenge: Achieve reliable Cr(VI) removal to below 0.1 mg/L in a high-flow effluent stream.

- Solution: We designed a specialized anion exchange resin system utilizing a highly selective macroporous resin, similar in matrix to 201X8 but with optimized functional groups for strong affinity towards chromate ions. The system was configured for continuous operation with an automated regeneration cycle.

- Results: The installed system consistently reduced Cr(VI) concentrations to non-detectable levels (below 0.05 mg/L), well within regulatory limits. This led to a 30% reduction in sludge disposal costs compared to the previous chemical treatment, demonstrating superior operational efficiency and environmental compliance. The client praised the system’s reliability and the significant reduction in their environmental footprint.

Ensuring Quality and Reliability: Our Commitment to Excellence

Our dedication to quality and reliability is fundamental to our operations. Every batch of ion exchange resin undergoes stringent quality control processes and is manufactured in facilities adhering to ISO 9001 standards. This commitment ensures consistency in product performance, capacity, and physical stability. We also comply with relevant industry standards such as ANSI/AWWA B500 for ion exchange materials, where applicable, further solidifying our authoritativeness in the market.

With over 15 years of experience in the ion exchange resin industry, we have cultivated long-standing partnerships with global leaders in power generation, petrochemicals, and municipal water treatment. Our robust internal testing procedures, including accelerated aging tests and dynamic column performance evaluations, provide verifiable test data that underscores the durability and efficiency of our resins. These rigorous tests ensure our products withstand the demanding conditions of industrial applications, providing our clients with peace of mind and predictable operational outcomes.

Frequently Asked Questions (FAQ)

- Q1: What is the typical service life of Strong Base Anion Exchange Resin 201X8?

- A1: The service life typically ranges from 5 to 10 years, depending on the feed water quality, operating conditions (temperature, regenerant type/concentration), and frequency of regeneration. Proper pre-treatment of feed water can significantly extend resin life.

- Q2: Can 201X8 handle high levels of organic matter?

- A2: Yes, as a macroporous resin, 201X8 has excellent resistance to organic fouling compared to gel-type resins. Its larger pore structure allows for easier desorption of organic foulants during regeneration, making it ideal for treating waters with moderate to high organic content. However, severe organic fouling may require specific pre-treatment or specialized resin types.

- Q3: Is the resin compatible with different regenerants?

- A3: Strong Base Anion Exchange Resin 201X8 is typically regenerated with caustic solutions (e.g., Sodium Hydroxide, NaOH). The concentration and flow rate of the regenerant are critical for efficient restoration of the resin’s exchange capacity. Our technical team can provide specific regeneration protocols.

- Q4: What are the primary differences between Type I and Type II strong base anion resins?

- A4: Type I resins (like 201X8) utilize trimethylamine, offering higher chemical stability, greater capacity for silica removal, and resistance to higher temperatures. Type II resins typically use dimethylethanolamine, offering higher regeneration efficiency and better rinse characteristics, but with lower thermal stability and reduced effectiveness for silica removal at higher temperatures.

Logistics and Support: Ensuring Trustworthiness and Seamless Operations

Our commitment extends beyond product quality to ensure a seamless and trustworthy experience for our B2B clients.

- Lead Time and Fulfillment: We maintain a robust supply chain and strategically located warehousing to ensure competitive lead times for our ion exchange resin products. Standard orders for 201X8 typically have a lead time of 2-4 weeks, with expedited options available for urgent requirements. We provide transparent communication on order status and delivery schedules.

- Warranty Commitments: All our resins, including Strong Base Anion Exchange Resin 201X8, are backed by a comprehensive product warranty covering manufacturing defects and ensuring performance specifications are met upon delivery. Specific warranty terms and conditions are provided with each quotation, underscoring our confidence in product quality.

- Customer Support and After-Sales Service: Our dedicated technical support team comprises experienced chemical engineers ready to assist with resin selection, system design optimization, troubleshooting, and regeneration protocols. We offer post-purchase support, including resin analysis services to evaluate performance and remaining capacity, helping clients maximize the service life of their anion exchange resin systems.

Conclusion

The continuous evolution of ion exchange resin technology is central to modern industrial efficiency and environmental stewardship. From fundamental water demineralization to complex chemical separations, the advanced properties of resins like Strong Base Anion Exchange Resin 201X8 provide robust, reliable, and cost-effective solutions. By combining deep technical expertise with a commitment to quality, customized solutions, and unparalleled customer support, we empower industries to achieve their most demanding purity and process optimization goals.

References

- 1. International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems — Requirements.

- 2. American Water Works Association (AWWA). ANSI/AWWA B500-19: Standard for Ion Exchange Materials.

- 3. United States Pharmacopeia (USP). USP Water for Pharmaceutical Purposes.

- 4. Publicly available specifications and technical data sheets from major ion exchange resin manufacturers.

Hebei Lijiang Biotechnology Co., Ltd, is a new material manufacturer specializing in the production of high-performance special ion exchange resins.mixed bed resin suppliers It is a modern high-tech enterprise that integrates the research and development,production, sales, and service of resin materials and resin terminal products.ion exchange resin The company is committed to producing high-quality industrial grade, food grade,pharmaceutical grade, and nuclear grade resins.cation exchange resin It has passed ISO9001 management certification,SGS certification, and WQA international certification from the American Water Quality Association, and has obtained a national food hygiene license. Food grade resin products comply with FDA standards in the United States.super blog